|

|

|

South Africa, TFP3051 Installation

In September, Jeff Gouer of the Cutting Technologies Division (CTD)

of Komatsu America Industries traveled to South Africa to install

a TFP3051 Mark IIIα. This model, first available this past summer,

has the Fanuc 0i-MC CNC with relocated gas controls for easier access.

He installed the machine at a company that manufacturers animal feed pellet

making machines that are sold throughout Africa and Europe.

Jeff was impressed by how friendly and helpful everyone was

during his visit.

While there his hosts took him to a nearby wild animal reserve.

See some of the

Wildlife Photos he took while there.

In September, Jeff Gouer of the Cutting Technologies Division (CTD)

of Komatsu America Industries traveled to South Africa to install

a TFP3051 Mark IIIα. This model, first available this past summer,

has the Fanuc 0i-MC CNC with relocated gas controls for easier access.

He installed the machine at a company that manufacturers animal feed pellet

making machines that are sold throughout Africa and Europe.

Jeff was impressed by how friendly and helpful everyone was

during his visit.

While there his hosts took him to a nearby wild animal reserve.

See some of the

Wildlife Photos he took while there.

TFP3051 Case Study in February 2009 FFJournal

Cutting steel plate faster than laser or waterjet

Cutting steel plate faster than laser or waterjet

Look in the Plasma Technology section of the February 2009 issue of FFJournal

for a case study on how a company added a Komatsu Twister

TFP3051

5 x 10 ft. 150 Amp Fine Plasma cutting machine

to complement their existing laser and water jet machines.

Alvin Thacker, president of

Laser Fabrication & Machine Co. of Wellington AL

talks about personal experience in machine shops,

resulting in his setting up his business focusing on metal cutting

using laser and more recently water jet machines. Now with 4 laser

machines and one water jet he has added a Twister TFP3051 plasma

machine aimed at the 1/2 in. to 1 in. range where his other machines

were having problems cutting efficiently. He chose the Twister

because of the cut accuracy and cut quality.

Comparing the plasma system with his water jet he finds that the

water jet cuts thick plate slower, and costs more to run.

Comparing the plasma with

the laser he has found that the laser will struggle to cut 1/2 in. plate

at 60 IPM while the Twister will cut it at 120 IPM.

Also cutting plate that is rusty, oily, or has mill scale will cause

problems for laser, while it doesn't bother the plasma systems at all.

Setup time on the laser is also an issue, as it could take 1/2 a day

to get the parameters right for the plate to be cut, and then you need

to do it all over again for the next plate.

Links:

Article Summary.

| |

|

|

|

|

TFP3062 6x12 Added to Twister Product Line

New to the Komatsu Twister product line is the

TFP3062.

This 6 ft. by 12 ft. machine is

similar in design to the new

TFP3051 Mark IIIα 5 ft. by 10 ft. machine,

and provides a compact

solution when larger table size is needed, but the larger

machines of the

TFPL series

would require too much space.

New to the Komatsu Twister product line is the

TFP3062.

This 6 ft. by 12 ft. machine is

similar in design to the new

TFP3051 Mark IIIα 5 ft. by 10 ft. machine,

and provides a compact

solution when larger table size is needed, but the larger

machines of the

TFPL series

would require too much space.

The Twister TFP3062 and TFP3051 Mark IIIα

feature the new model Fanuc 0i-MC CNC,

and rearranged gas setup for easier operation.

The TFP3062 and TFP3051 feature Twister 30 kW (150 Amp) Fine Plasma torch that will cut Mild Steel up to 1" thick, Aluminum up to 5/8", and Stainless Steel up to 3/4". They also include the QuickSilver process that produces superior cutting speeds and edge quality when cutting Stainless Steel.

| |

|

Hybrid Plasma and Laser,

THB Series

The

Twister Hybrid THB6082

has both a 300 amp (60kw) fine plasma torch,

and a 3.2 kw laser on the same 8 by 20 ft. table.

It is capable of alternating plasma and laser cutting

on the same part. This allows you to take advantage

of the best of both cutting methods on one table without additional

setup.

The

Twister Hybrid THB6082

has both a 300 amp (60kw) fine plasma torch,

and a 3.2 kw laser on the same 8 by 20 ft. table.

It is capable of alternating plasma and laser cutting

on the same part. This allows you to take advantage

of the best of both cutting methods on one table without additional

setup.

The laser enables the machine to cut thinner material, and

cut smaller more accurate holes in plasma cut parts.

For many applications, high definition, Fine Plasma cutting

is all you need.

Click here to see why Twister Fine Plasma

may be all you need, or may compliment your existing

laser machine. If you really need laser, then consider

the

Komatsu Twister THB

Hybid Plasma and Laser Cutting Machine.

| |

Invest in Capital Equipment

Invest in Capital Equipment

Now is the time to buy a new

Komatsu Twister

fine plasma cutting machine.

Give us a call so we can explain how replacing your existing

machine can quickly start saving you money and time.

If your old machine is a

Rasor

5x10 or 4x8 excellent trade-in terms are available too.

Larger machines in the

TFPL Series

are also available. The photo on the left is a 10 ft. by 50 ft.

extended length TFPL machine. Extended lengths up to 100 ft. are

available.

For the ultimate machine, there is the

Tandem TFPV6084 with bevel cutting torch. This has two 300 Amp

torches on an extended length 8 ft. x 100 ft. table. This Tandem

machine is capable of

cutting two smaller plates independantly or cutting parts up to 25m (82 feet) if needed.

Also consider the

Twister THB

Hybrid Plasma and Laser machine,

capable of both plasma and laser cutting on the same part.

| |

Twister Fine Plasma

Twister Fine Plasma

Komatsu's

Twister Fine Plasma products represent

the latest technology in plasma cutting of metals

that started with the first line of Fine Plasma

cutting machines in 1989. In the 1990's through

today the Komatsu Fine Plasma technology has been

the backbone of the

Rasor Series

of Fine Plasma

Cutting Machines recognized for the high quality

precision cutting and outstanding service and support.

The Twister Series continues this tradition,

adding more power and patented technology enhancements that

produce superior cut surface finishes to laser

at a fraction of

the initial cost, production time, and production cost.

The Twister Series is available to expand your production

capacity and to start saving now!

Komatsu Fine Plasma power supplies, torches, and cutting machines

are designed and built by Komatsu Industries Corporation (KIC).

KIC Coprorate Profile PDF File (1.61Mb) KIC Overview and History PDF File (313Kb)

KIC Overview and History PDF File (313Kb)

In the US KIC Presses are sold and serviced by

Komatsu America Industries, Press Technology Division.

| |

TFP3051 30 kW 5 x 10 ft.

TFP3051 30 kW 5 x 10 ft.

The

TFP3051

features a 5 ft. by 10 ft. cutting

surface and the Twister 30 kW (150 Amp) Fine Plasma

torch. It will cut Mild Steel up to 1" thick,

Aluminum up to 5/8", and Stainless Steel up to 3/4".

It includes the QuickSilver process that produces

superior cutting speeds and edge quality when cutting

Stainless Steel. Cutting speeds are improved and dross

is reduced due to

the high power plasma unit and high speed Twister

gas. Pierce times are reduced due to incorporating

automatic gas change during the touch sensor cycle.

Cut quality is improved by control of main gas flow

and arc mode based on hole size. Spraying anti-spatter

directly through the torch improves hole cut quality

and consumables life. The push-pull zoned exhaust system

greatly reduces fumes while cutting. A mechanical

spatter splash shield is activated during piercing.

The February 2007 issue of FFJournal has an article titled

"Winds of Change, A new kind of twister hits Hickey Metal Fabrication".

This article describes Hickey Metal Fabrication's

experience with the

Twister TFP3051

Order the

TFP3051 with the High Body Factory Installed Option

to increase the Z-Axis stroke from 5 in. to about 12 in.

This allows cutting of square pipe and other structural members

without decreasing accuracy when cutting sheet metal and plate.

| |

TFPL Series 30 and 60 kW, 8 or 10 ft. by 20 or 40 ft.

The

TFPL Series features larger table sizes,

and all of the cutting technology

enhancements described above with the TFP3051.

Tables are available in 8 or 10 ft. widths

and 20 or 40 ft. lengths. Choose either

the 30 kW (150 Amp) or 60 kW (300 Amp)

Twister Fine Plasma Unit and Torch.

The 60 kW Fine Plasma includes the cutting

capabilities of the 30 kW, but extends the

maximum cutting capacity for Mild Steel to

1.5" by using the higher plasma power unit and larger

nozzle sizes. A light curtain and tape emergency

stop are included for safety. Ultra-solid carriage,

and linear guides achieve high quality, precision

cutting.

Extended length machines are available in 1 meter increments

up to around 100 feet.

See some extended length TFPL Machines installed in China...

The

TFPL Series features larger table sizes,

and all of the cutting technology

enhancements described above with the TFP3051.

Tables are available in 8 or 10 ft. widths

and 20 or 40 ft. lengths. Choose either

the 30 kW (150 Amp) or 60 kW (300 Amp)

Twister Fine Plasma Unit and Torch.

The 60 kW Fine Plasma includes the cutting

capabilities of the 30 kW, but extends the

maximum cutting capacity for Mild Steel to

1.5" by using the higher plasma power unit and larger

nozzle sizes. A light curtain and tape emergency

stop are included for safety. Ultra-solid carriage,

and linear guides achieve high quality, precision

cutting.

Extended length machines are available in 1 meter increments

up to around 100 feet.

See some extended length TFPL Machines installed in China...

The TFPV Series features a bevel cutting 60 kW torch

that can be used to accurately and efficiently cut welding grooves.

A CCD Camera is used in second cut positioning to compensate

for piece movement after the first cut.

|

|

Refurbished Rasors

Refurbished Rasors

Not ready for a new Twister machine? We now have

Rebuilt and Recertified Rasor cutting machines that are available for immediate

delivery.

The

KCR-0448

has a

4 x 8 ft. table with 40 Amp G940 Fine Plasma.

The

KCR-0951

has a

5 x 10 ft. table with 90 Amp G990 Fine Plasma.

It can also be reconfigured with 120 Amp G9120 Fine Plasma if desired.

See an example of a KCR-0951 being rebuilt from start to finish...

Factory Rebuilt 40 and 90 Amp Fine Plasma Power Units are available.

For a 5 x 10 ft. table with more power consider a new

TFP3051

or the 6 x 12 ft.

TFP3062

with 150 Amp Fine Plasma. One is ready for delivery to your shop now!

Both new Twisters and Refurbished machines can be delivered with

the

Twister and Rasor Server

software for Windows. So you can

upgrade your software and get the new machine at the same time!

| |

Rasor Quality Program

Rasor Quality Program

We want your Rasor to economically produce the best quality parts.

We offer

Preventative Maintenance Programs (PSPs), Mechanical Overhaul Services, and Operator Training Programs.

Call for details on how we can improve your machine's performance.

Planned Service Programs:

We offer

3 one year programs to fit within your budget.

Benefits are decreased down time, better part quality, and they may

save you money on service, parts, and consumables.

Mechanical Overhaul Service:

Save time and money by giving your Rasor a much needed overhaul.

Doing an overhaul now can save you money compared with service calls

to fix things later. Save time and money on the parts you cut by getting

optimum cut quality and reducing secondary operations. Save money

on consumable parts by reducing cut time, recuts, and premature

electrode and nozzle failure.

Make your old Rasor machine cut like new again. Let us overhaul your X, Y, and Z Axis. Services include new racks and pinions, rails and bearings, belts and much more.

Operator Training:

A well trained operator can make a big difference in terms of

production time, down time, part quality, and consumable cost.

| |

|

|

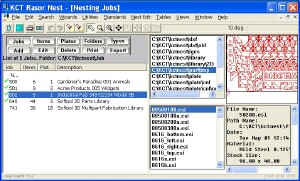

Rasor Server Software

Rasor Server Software

Special Package Pricing now through February 28:

All 4 titles for less than Rasor Server Alone!

Upgrade now to the

Rasor Server

for Windows software. Several different packages

are available including various combinations of

Rasor Server,

Rasor Nest,

PathMaster, and

SofTool 3D Multi-Part Fabrication Library. Demos are available for download. Call for the login id and password.

Both new Twisters and Refurbished machines can be delivered with

the

Twister and Rasor Server

software for Windows. So you can

upgrade your software and get the new machine at the same time!

| |

|

You are receiving

the Twister Newsletter because you have expressed an interest in Komatsu Fine Plasma Twister or Rasor products.

For comments or

questions regarding this newsletter, please

contact the webmaster@komatsuplasma.com.

UnSubscribe

| Subscribe

|

Cutting Technologies Division

Komatsu America Industries LLC

92 Cummings Park

Woburn, MA 01801

www.komatsuplasma.com

Phone: 800-707-2767 Fax: 781-782-0506

|

|

For a complete description of

our practices with respect to use and disclosure

of your information, click here: Privacy

Copyright © 2009 Cutting Technologies Div. KAI LLC

All rights reserved. |

| | | |